Laser Welding Services

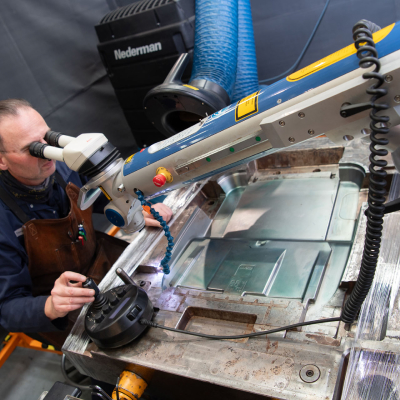

Our skilled technicians can ensure that damage or modification to your mould is skilfully welded exactly where needed, ensuring rework post-weld is kept to a minimum.

Our skilled technicians can ensure that damage or modification to your mould is skilfully welded exactly where needed, ensuring rework post-weld is kept to a minimum.

Laser Welding Services

As one of a select group of companies that offer laser welding, our skilled technicians can ensure that damage or modification to your mould is skilfully welded exactly where needed, ensuring rework post-weld is kept to a minimum.

For small “nicks and bumps” our while you wait service is ideal for customers in line stop emergencies.

Our welding machine is capable of welding:

The benefits of laser welding have been a game-changer for customers, with the ability to repair parts previously deemed scrap. Our high-tech welding machine can:

Laser welding is the process in which either metals or thermoplastics are connected using a laser gleam. This then forms a weld. This procedure can also be used in thicker materials and may produce a slender, deeper weld.

When looking at how laser welding works, there are two optional key modes: keyhole welding and conduction welding.

What is laser welding? Read our blog to find out more!

Keyhole Welding – This method is conducted by the laser gleam heating the metal so that the surface evaporates and penetrates into the metal. This melting procedure then forms a keyhole. This method requires a high-powered laser with a power output of above 105W/mm2.

Conduction Welding – In this procedure, the material goes through a heat process that is above the metal’s thawing point, making sure it does not evaporate. This procedure is most suitable for welds that don’t require high weld strength. A benefit of thermal conduction welding is that it comes out aesthetically and highly smooth, offering high quality, professional finish.

As well as offering a laser welding machine on tracks to allow us to work on larger projects, we have a smaller fixed laser welding machine to allow us to work on the smaller jobs. This ensures our team can cover all your bases and provide equipment for a range of your goods. Our welding services also offer a chance to put life into new products, meaning replacements are limited and waste is reduced.

Whether you’d like to send items to us via your own courier, or you’d like to make use of our dedicated collection and delivery service, we’re able to offer a nationwide laser welding service. A large bonus Pro-Moulds offer is a collection and drop off schedule. We will simply retrieve your good from you, take it back to our facility and drop it back once all tasks are complete. Simple!

Based in Nottinghamshire, close to the M1 motorway, our team are able to cover the rest of the UK easily including Derby, Leicester and Sheffield so don’t hesitate to get in touch! Call 01623 904 417 to arrange a pick up or delivery.