Plant List

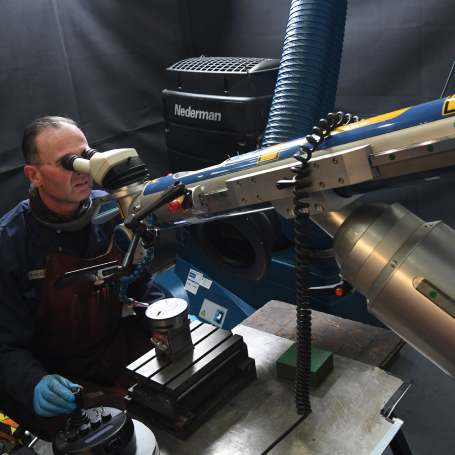

What’s in our toolroom?

Over the past 25 years, we have filled our toolroom with a wide range of modern technology, giving us the equipment and resources needed for all our services.

These machines and softwares cover processes from tool design to injection moulding or tool making, ran by experienced and skilled teams who know exactly what they’re doing! As a customer, these upgraded stations offer you fast results, consistency and a high performance, coming together to create the best possible outcome.

Spark Erosion

- Solid Sink Exeron 313 with 5 Position Tool Changer & `C Axis

- Solid Sink Exeron 310 with 20 Position Tool Changer & `C’ Axis

- Agie Charmilles Cut E600 Wire Eroder

Material Handling

- 10 Tonne overhead crane ( 2 x 5 tonne ) loading and assembly bay

- 2.5 Tonne overhead crane in machine shop

- 3 tonne Fork Truck

Other Plant Hire includes...

CAD Design

With all the modern technology out there, Pro-Moulds have mastered the best CAD and CAM Systems, offering a new and more detailed approach to design and communication.

- Cimitron

- Solidworks

- Mastercam X5 Design

Grinding

- Jones & Shipman 1300 Cylindrical Grinder with D.R.O.

- 2 off Jones & Shipman 540P Surface Grinder with Optidress and D.R.O.

- 2 off Jones & Shipman 540E Surface Grinder with D.R.O.

- Jones & Shipman 540 Surface Grinder

- XYZ 1632 with D.R.O.

Turning

- XYZ RLX 555

- XYZ SLX 1630

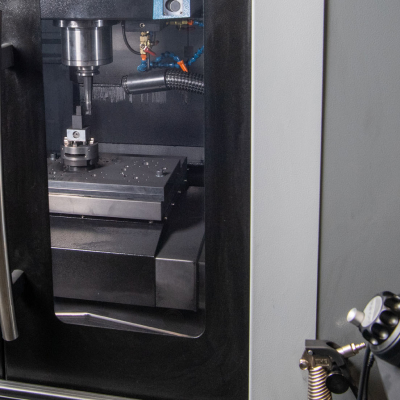

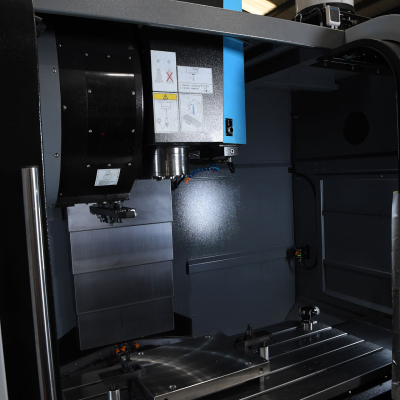

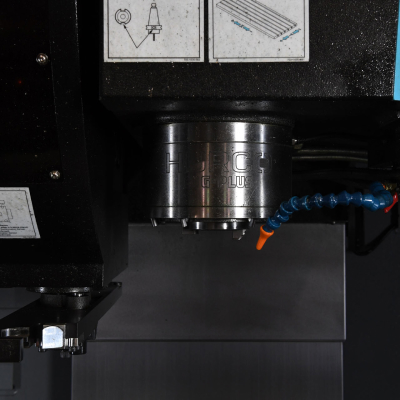

Milling

- Haas VF-3 Machining Centre with 20 Position Tool Changer

- XYZ 1600LR VMC with 24 Position Tool Changer

- Hurco VMX42i VMC with 30 Position Tool Changer

- Hurco VM1 VMC with 24 Position Tool Changer

- XYZ 2OP VMC with 6 Position Tool Changer

- XYZ 2000 Vertical Milling Machine with D.R.O. & Automatic Traverse

- 2 off K.R.V. 2000 Vertical Milling Machine with D.R.O. & Automatic Traverse

Drilling

- Asquith Radial Drilling Machine 5’ Arm

- Bead Blasting

- 800 x 600 x 700 Cabinet (fine, medium and coarse)

Hardening

- Carbolite Hardening Furnace (for heat treatment of all die steels)

Hobbing

- 3 off Barber-Coleman Hobbing Machine (Various Sizes)

- Automatic key seater keyway machine