Tool Design

Tool design services across Nottingham and the rest of the UK

In-house designers using modernised and efficient technology

Tool design services across Nottingham and the rest of the UK

In-house designers using modernised and efficient technology

Before our toolmakers can get their hands on the mechanical part, Pro-Moulds will work with you to ensure your initial design and thought process can come to life, creating both simple and detailed briefs to get the ball rolling! The whole company is proud of the fact we work by your side through the entire toolmaking process, taking you from the initial phone call all the way to the final product.

When thinking about tool design, the initial scope is just as important as the creation and engineering process. This starting point can benefit your tool’s life span, quality of use and function just as much as the assembly. The designer’s aim is to make a product with a steady tool life, ensuring it is accurately fit for purpose and won’t require regular replacement.

For an in depth look into the journey of tool design, have a read through our blog on the tool design process.

Please contact us on 01623 904 417 to get your design journey started!

Tool Design is the starting point for any manufacturing process. Combining analysis, design, construction and application, this first step is key to creating successful tools. To carry this task out professionally, Pro-Moulds has a team of highly skilled workman combining their knowledge of machine practise, tool making plus design and manufacturing procedures.

The primary purpose of this stage is to increase production whilst maintaining the overall quality and cost. The designer aims to increase production rate and be cost-effective whilst also ensuring design tools are safe and easy to use by all.

Visit our Plant List to view all softwares and machinery available in our toolroom.

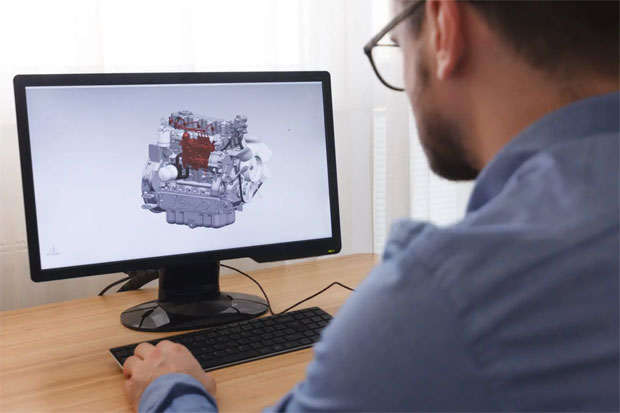

Here at Pro-Moulds we have gained successful access to the best technology and machinery in the industry, updating our equipment to suit the needs of the team and the customer. This also includes investing in modern CAD and CAM softwares to ensure moulds, designs and training is done to high standards! Some of the softwares we have include Cimitron, Solidworks and Mastercam X5 Design.

Computer Aided Design also known as CAD is a modern and adaptable piece of technology used all around the world. This software is vital when talking about tool design, providing the needs for creation, modification, analysis and optimisation. Pro-Moulds have found the use of CAD has effectively increased the designers productivity, improving the quality of our in-house designs and also improved communication through thoughts and ideas. Our design team uses this software to create both 3D and 2D models, giving you a clear and detailed view before the toolmaking process.

Please don’t hesitate to get in contact with us if you have any questions or ideas based around CAD or CAM design.