Tool Repair, Modifications & Servicing

Covering the whole of the UK

Covering the whole of the UK

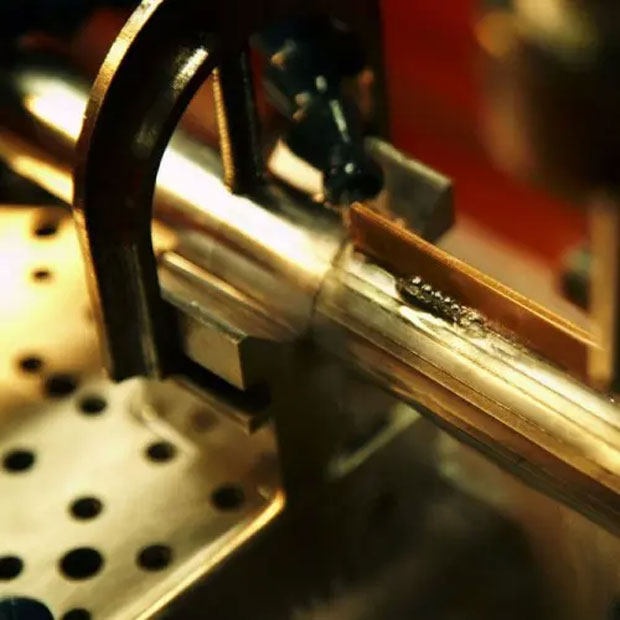

Here at Pro-Moulds (Midlands) Ltd, we pride ourselves on the level of service that we offer plus our under-one-roof toolmaking service that extends to tool repair, modification and maintenance up to 10,000kg.

No matter how carefully monitored, the gremlins are always waiting to get a foot in the mould. Our repair setup is designed to cope with your unexpected issues, offering mould tool repair and die repair. We can quickly collect, repair and return your mould to pre-gremlin glory.

Our tool repair service is utilised by a range of customers across the automotive, manufacturing and engineering sectors and we’ve earned a reputation for the quality and speed of our tool repair service.

At Pro Moulds a lot of our daily operation involves tool modifications. Whether that change is purely aesthetic or an essential engineering change, modifying your existing mould will keep costs and machine downtime to a minimum.

To help your business maintain maximum cost-effective productivity, we offer a range of service options from planned maintenance schedules to as-and-when options. Whatever the origin of your tools, we endeavour to service or repair them in as short a time as possible. A regular service schedule can be of great benefit to businesses operating round the clock. Providing smoother production flow and minimising downtime. Contact Pro Moulds today and discuss your design, moulding, maintenance and service needs.

As with all of our toolmaking services, we offer a nationwide service and can arrange the collection and delivery of your items once we have completed the work. We have a large scale workshop, allowing us to work on tool repair jobs both large and small.

Whatever your tool repair, mod or maintenance needs, we offer free advice to all potential customers over the phone, just call us on 01623 904 417 and we’ll be happy to help.

To avoid maintenance or reduce the need for repairs, have a read through our blog on how to maintain tool quality!

If you’ve been using the same tool/die for a long time the chances are that it’ll need to be serviced and taken care of. A poorly maintained tool or die can end up being very expensive for you and result in errors within your finished products. Our repair team work to keep all systems running, focusing on mould tool repair and potential physical damage.

Through proper care and servicing, you’ll be able to keep your manufactured products precise and up to date.

Get in touch today on 01623 904 417 and get a quote from the experts.

Covering a range of industries, our repair engineers work hard to get things fixed quickly and efficiently! If your daily activities include sharpening and cutting edges, replacing, cleaning and inspecting dies will become an essential. Covering a range of different dyes, our experts use experience and skills to repair and potentially replace any damage or wear and tear, whether that of been over time or during the design process.

Call us on 01623 904 417 for any tool and die repair enquires or if you are looking for local repairs visit the Toolmaking Nottingham page or contact us for work in Derby, Leicester and any surrounding areas.

Cleaning and inspecting your die is key in keeping the standards high and ensuring you are using the best quality equipment at all times. Some things to look for when inspecting die could be: loose fasteners, missing pins, broken springs, chipping and debris buildup.

Thanks to our in-house facilities, no matter the tool or die, our machinery and team have got everything covered! When it comes to repairs, just like most things, there is a great scope with what may need doing, this can range from a single loose screw to a whole re-fixture. As we carry out both the design and toolmaking process on site, this gives us a greater insight and knowledge to any issues that may arise, getting your tools up and working in no time.

With our range of highly advanced technology and machinery, Pro-Moulds have taken the time to thoroughly learn about each piece of equipment available. The team carry out thorough checks to ensure our tool room is working to the best of its ability, keeping on track of any repairs needed on our end.

Get in contact today for any repair or maintenance services!