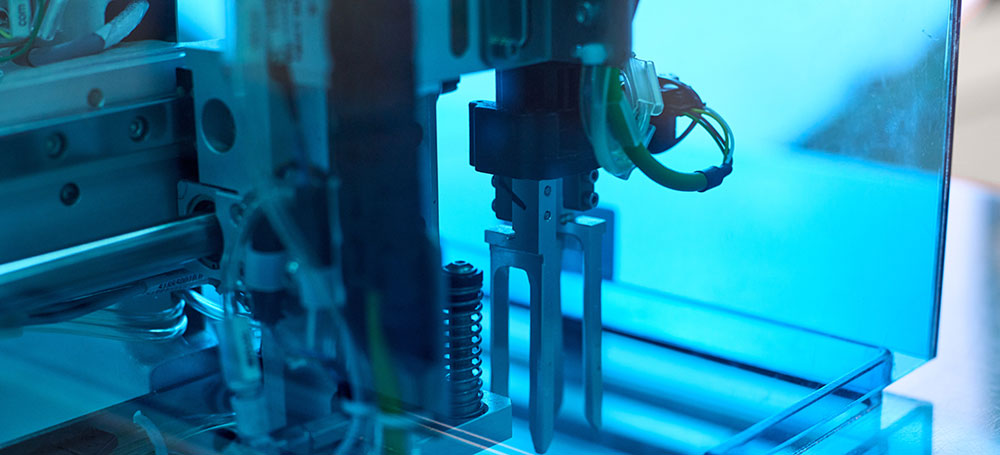

Automation in the injection moulding industry offers a wide range of advantages for both the manufacturer and the customer. These benefits significantly impact efficiency, productivity, and overall performance, allowing injection moulding to come a flexible, adaptable field.

- Production speed and volume

Automation enables injection moulding machines to operate at higher speeds which ultimately increases production rates. By automating various processes such as material handling, manufacturers can achieve shorter cycle times and meet production demands.

- Precision and consistency

Automation provides better control over the injection moulding process and higher quality results. Automated systems are designed to follow strict instructions, reducing the risk of human error, and wasted produce and maintaining quality control.

- Reduced waste:

As a result of accurate results, these modern systems help minimise material waste by precisely controlling the process from start to finish. This not only saves costs but also contributes to sustainable manufacturing practices.

- Low labour

By automating repetitive tasks and reducing the need for manual labour, businesses can save money on headcount or prioritise other tasks. With automation, the need for manual in areas such as handling, inspection, and packaging is reduced or eliminated and allows companies to assign skilled, intricate tasks.

- Improved workplace safety

The injection moulding industry comes with various hazards, including dangerous temperatures, heavy machinery, and power tools. Automation helps to control these risks by removing or reducing the need for human involvement and replacing them with robotic systems.

- Quality Control

Automation technologies and softwares can be used for real-time monitoring and quality control throughout the production process. Equipment such as cameras and sensors can be used to pick up defects, dimensional accuracy, and abnormalities.

- Customisation

One of the biggest benefits of automation is the design scope the systems offer. Automation can be programmed to accommodate various product designs and specifications and offer the ability to change moulds, produce 3D models and use cad softwares for diverse production and a competitive edge.

- Customer satisfaction

With all these advantages in mind, they all come together to improve customer satisfaction. Automation doesn’t only make the production process quicker and higher in quality but also comes with communication features such as barcoding, tracking, auto messaging services and customer support.